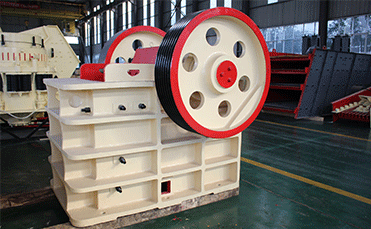

Jaw Crusher

Jaw crusher is easy to install, operate and maintain. As per feedback, our experts will make continuous improvements on our products to meet customers' changing needs. Every feature of jaw crusher has been carefully designed to provide superior quality and performance. It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc. Jaw crusher has competive jaw crusher price for you.

Easy ways to get the answers you need. Service Online

Jaw Crusher Machine Introduction

Jaw Crusher Working Principle

The motor drives belt and belt wheel, the eccentric shaft causes the movable jaw to move down and up, forward and backward, the angle between toggle plate and movable jaw becomes bigger when the movable jaw moves up, so that the movable jaw moves toward the fixed jaw, and the materials are pressed, crushed, or cut, as a result, the aim of crushing is accomplished.

Jaw Crusher Advantage

1. Jaw Material Mn13Cr2

2. Toggle Plate Casting Steel

3. Adjustment Block: Casting Steel

4. Side Plate Material: Mn13Cr2

5. Cover of Frame: Weldment Carbon Steel

6. Main Shaft 4140(40Cr)

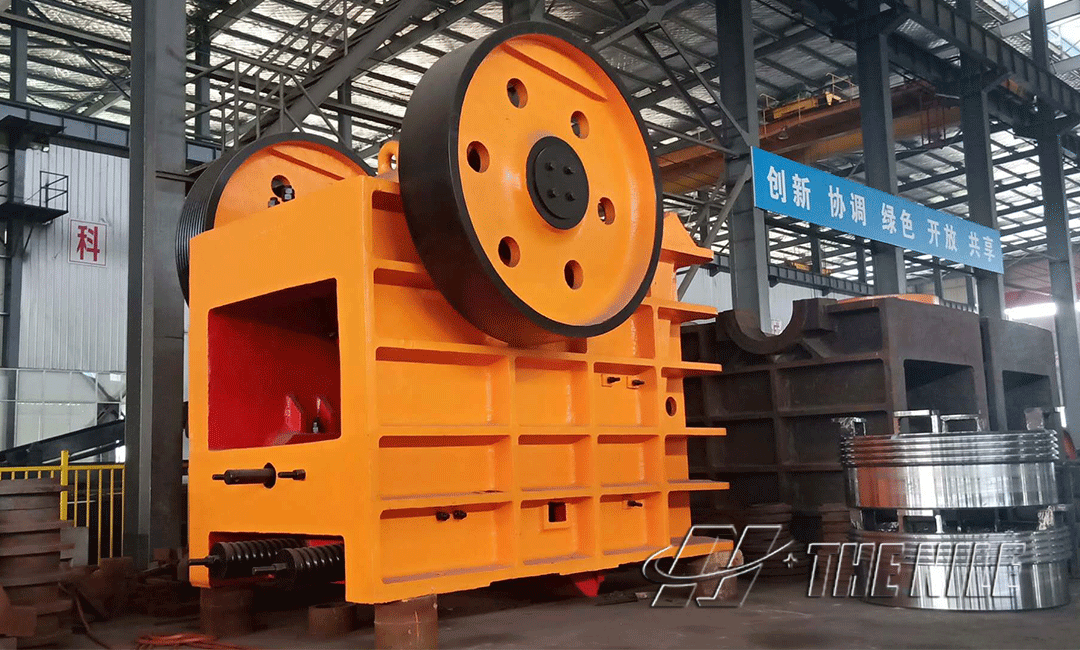

Customer visit the factory

Kenya customer visit our factory,and buy the big jaw crusher machine to crushing gold ore stone.

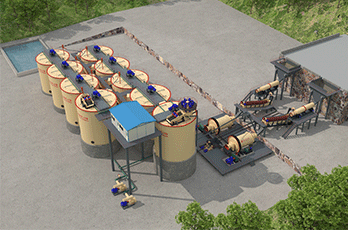

This series of jaw stone crushers are most suitable for crushing various soft and hard ores with compressive strength not higher than 300MPa (megapascals), and the maximum size of the crushed materials shall not be greater than the specifications in the technical parameter table.

This gold stone jaw crusher machine are mainly used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industrial sectors for medium and fine crushing of various medium-hard ores and rocks.

Jaw Crusher Working Principle

The motor drives belt and belt wheel, the eccentric shaft causes the movable jaw to move down and up, forward and backward, the angle between toggle plate and movable jaw becomes bigger when the movable jaw moves up, so that the movable jaw moves toward the fixed jaw, and the materials are pressed, crushed, or cut, as a result, the aim of crushing is accomplished.

Jaw Crusher Advantage

1. Jaw Material Mn13Cr2

2. Toggle Plate Casting Steel

3. Adjustment Block: Casting Steel

4. Side Plate Material: Mn13Cr2

5. Cover of Frame: Weldment Carbon Steel

6. Main Shaft 4140(40Cr)

Customer visit the factory

Kenya customer visit our factory,and buy the big jaw crusher machine to crushing gold ore stone.

Jaw Crusher Machine Technical Data

| Model |

Feeding Opening Size (mm) |

Max feed size (мм) |

Discharging range (мм) |

Capacity (т / h) |

Power (кw) |

Weight (t) |

Dimensions (mm) (LxWxH) |

| PE-150×250 | 150×250 | 120 | 10-40 | 1-4 | 5.5 | 1.1 | 880×750×940 |

| PE-150×750 | 150×750 | 120 | 10-40 | 10-20 | 15 | 2.2 | 1260×1400×900 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-20 | 15 | 3 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-60 | 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 55 | 12 | 1980×2080×1870 |

| PE-600×900 | 600×900 | 500 | 65-160 | 90-180 | 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 110 | 29 | 2660×2430×2800 |

| PE-800×1060 | 800×1060 | 640 | 80-150 | 130-330 | 110 | 29.8 | 2710×2430×2800 |

| PE-900×1060 | 900×1060 | 685 | 80-150 | 230-390 | 110 | 33 | 2870×2420×2940 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 110-132 | 58 | 3380×2870×3330 |

| PE-1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 110-160 | 69 | 3480×2876×3330 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 4200×3300×3500 |

| PEX250×750 | 250×750 | 200 | 15-60 | 13-35 | 30 | 6.5 | 1380×1750×1540 |

| PEX250×1000 | 250×1000 | 200 | 15-60 | 16-52 | 37 | 7 | 1560×1950×1390 |

| PEX250×1200 | 250×1200 | 200 | 15-60 | 20-60 | 45 | 9.7 | 2140×2096×1500 |

| PEX300×1300 | 300×1300 | 240 | 20-90 | 20-100 | 55 | 15.6 | 2720×2210×1600 |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now