Disc vacuum filter

The disc vacuum filter is a device that uses a vacuum as a filtering power to perform solid-liquid separation of the slurry.

Easy ways to get the answers you need. Service Online

Product description

The disc vacuum filter is a device that uses a vacuum as a filtering power to perform solid-liquid separation of the slurry. It is suitable for the filtration and dehydration of fine particle materials in industries such as mining metal ores, non-metal ores, environmental sludge, cement, and building materials.

Features

(1) The fan-shaped filter plate has even distribution of dewatering pores, reasonable porosity, large rib size, and is made of high-strength engineering plastic, which has improved its life by 2-3 times.

(2) The filtrate tube has a large number of filtering surfaces and a large volume in the distribution head and abdominal cavity, which improves the pumping rate and the filtrate discharge effect.

(3) Abrasion-resistant nylon, single or multifilament filter cloth makes the cake removal rate high and not easy to block, and has a long service life.

(4) Filter cloth automatic cleaning device keeps its good dewatering effect.

(5) Triple seal without leakage.

(6) The stepless speed change of the main drive, which is adjusted according to the concentration and flow of the material, in order to achieve the ideal working effect.

(7) Uniform cake thickness.

(8) The service life of the friction plate reaches more than ten years.

Working principle

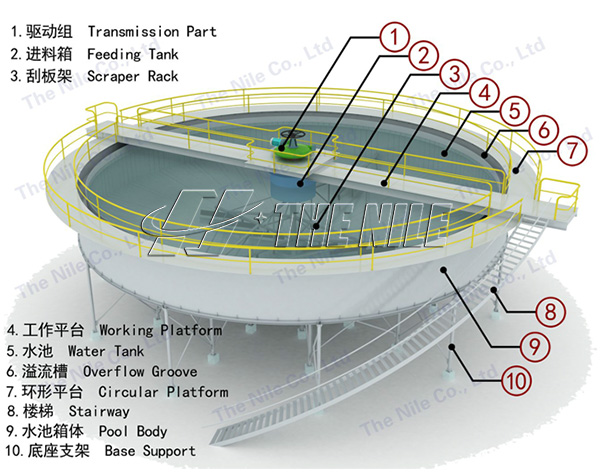

The disc vacuum filter consists of discs of individual fan segments. Each fan-shaped sheet is an independent filter unit, and a filter cloth is made of filter cloth to cover the fan-shaped sheet to form a filter chamber. The filter disc is driven by a motor through a speed reducer and an open gear transmission. The filter disc rotates clockwise. The slurry in the filter chamber in the adsorption zone uses a vacuum pump to create a pressure difference on both sides of the filter medium. After the cake, the stirrer is rotated to prevent solid precipitation. After the filter cake leaves the liquid surface, the water is continuously removed under the action of vacuum. The filtrate passed through the filter cloth, passed through the filtrate tube, and was discharged from the dispensing head. In the discharge area, the filter cake is discharged into the discharge trough by back-blowing discharge, and the whole operation process is continuously circulated.

Technical Parameters

| Filter disk diameter (mm) | 2.0型 | 3.0型 |

| Filtration area (㎡) | 5-60 | 48-120 |

| Number of filter discs | 1--12 | 4-10 |

| Number of filter fans per plate (a) | 18(20) | 18(20) |

| Spindle motor power (kw) | 2.2-5.5 | 5.5-11 |

| Power of stirring motor (kw) | 3-7.5 | 7.5-15 |

| Unloading method | Back blowing | Back blowing |

| Capacity kg /h·㎡ | 701-1250 | 701-1250 |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now