Ball Mill

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final products between 0.074 mm and 0.4 mm in diameter.

Easy ways to get the answers you need. Service Online

The ball mill is the key equipment for crushing the material after it is broken. Ball Mill is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal mineral processing and glass ceramics and other production industries, all kinds of ores and other grinding materials for dry or wet-type grinding.

Outstanding Advantages

Save Energy

Using full hydraulic operation, easy to use, easy to realize automation, its reliability and life greatly improved;

Flexible design of discharging department

The discharging port design is reasonable, the customer can match the iron remover according to their own needs

Save Energy

Using full hydraulic operation, easy to use, easy to realize automation, its reliability and life greatly improved;

Flexible design of discharging department

The discharging port design is reasonable, the customer can match the iron remover according to their own needs

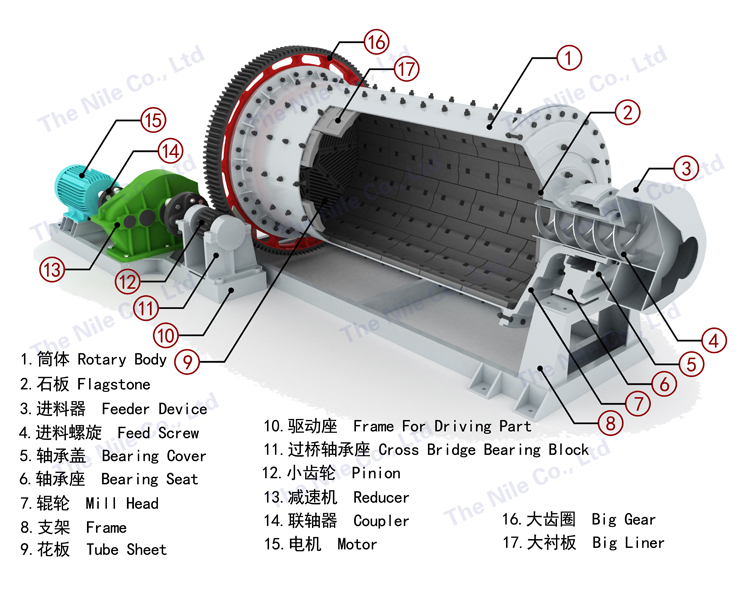

Rotary Department

The cylinder, liner, medium, silo board and discharging grate of the rotary section are all made of high quality original combination.

Feeding volume of feed department is large

Reasonable inlet design increases the feed quantity

High grinding efficiency, good liner quality

The lining plate and the abrasive body adopt alumina ceramics, quartz, silex or special material, the hard mineral uses the iron-free pollution design.

Using closed systems to reduce dust

Ultra-fine ball mill and classifier forming closed systems, negative pressure conveying, no dust, reduce damage to human body

Ball Mill Technical Data

| Model | Ball weight (t) | Feed size(мм) | Output | Motor power (kw) | Weight |

| Size | (T) | ||||

| mm) | |||||

| Ф900×1200 | 1 | ≤20 | 0.074-0.4 | 18.5 | 4 |

| Ф900×1800 | 1.5 | ≤20 | 0.074-0.4 | 22 | 4.8 |

| Ф1200×2400 | 3.5 | ≤25 | 0.074-0.4 | 30 | 9.5 |

| Ф1200×4500 | 5 | ≤25 | 0.074-0.4 | 45 | 13.1 |

| Ф1500×3000 | 7 | ≤25 | 0.074-0.4 | 75 | 16 |

| Ф1500×4500 | 10 | ≤25 | 0.074-0.4 | 110 | 19 |

| Ф1830×3000 | 10 | ≤25 | 0.074-0.4 | 130 | 25 |

| Ф1830×3600 | 12 | ≤25 | 0.074-0.4 | 155 | 32 |

| Ф1830×4500 | 15 | ≤25 | 0.074-0.4 | 155 | 33.7 |

| Ф2100×3600 | 22.5 | ≤25 | 0.074-0.4 | 210 | 45.8 |

| Ф2200×4500 | 28 | ≤25 | 0.074-0.4 | 280 | 46.5 |

| Ф2400×4500 | 30 | ≤25 | 0.074-0.4 | 380 | 65 |

| Ф2700×4500 | 43 | ≤25 | 0.074-0.4 | 480 | 97 |

| Ф3200×4500 | 59 | ≤25 | 0.074-0.4 | 630 | 156.5 |

| Ф3600×4500 | 75 | ≤25 | 0.074-0.4 | 1000 | 162 |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now