Water cyclone separator

Hydro-cyclone is a kind of equipment for classifying the ore pulp by use of centrifugal force. It has no motion and dynamic parts,and needs to be matched with corresponding slurry pump. It is mainly used in ore dressing industry for classifying, dewatering and desliming.

Easy ways to get the answers you need. Service Online

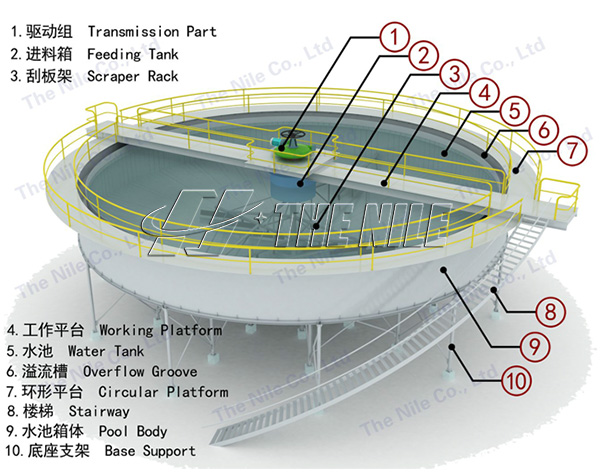

Introduction

Hydro-cyclone is a kind of equipment for classifying the ore pulp by use of centrifugal force. It has no motion and dynamic parts,and needs to be matched with corresponding slurry pump. It is mainly used in ore dressing industry for classifying, dewatering and desliming.

Hydro-cyclone is a kind of equipment for classifying the ore pulp by use of centrifugal force. It has no motion and dynamic parts,and needs to be matched with corresponding slurry pump. It is mainly used in ore dressing industry for classifying, dewatering and desliming.

Hydro-cyclone has been extensively used for closed circuit grinding and classification system , thickening, desliming, dewatering , tailings filling, damming, recovery processes in ferrous, nonferrous metal and nonmetal mine industries, and is deeply popular with customers due to high classification efficiency, simple structure, large throughput, and small occupied area.

Working principle

In closed circuit grinding system, it features high classification efficiency and fine over fall fineness under high mine concentration. Classification efficiency is higher for 5-10% than common screw grader. It benefits for enhancing grader utilizing coefficient. Choose proper specification and mode of cyclone according to grinding processing capacity, over fall fineness and sedimentation concentration.

Main features

1.Simple structure; light and nimble; no moving part

2.Low maintenance charge; easy to attach and detach; save floor space; low construction expense

3.Large processing capacity

4.The classification particle size can reach 10μm

Technical parameter

| Model |

Diameter (mm) |

Overflow Pipe Dia.(mm) |

Bottom Exit Dia.(mm) |

Cone Angle (°) |

Max. Feeding Size(mm) |

Capacity (m³/h) |

Classify Size(µm) |

| FX500 | 500 |

130, 140, 150, 160, 180, 220 |

35, 45, 50, 65, 70, 80, 90, 100 |

10 20 25 |

10 | 140-220 |

74-200 74-200 74-150 |

| FX350 | 350 |

80, 90, 105, 115, 120 |

30, 35, 40, 45, 50, 60, 70 |

15 20 25 |

6 | 60-105 |

50-150 50-150 50-120 |

| FX300 | 300 |

55, 65, 80, 100, 120 |

20, 25, 30, 35, 40 |

15 20 25 |

5 | 45-90 |

50-120 50-150 50-150 |

| FX250 | 250 |

60, 75, 80, 100, 120 |

16, 18, 20, 25, 30, 35, 40 |

10 15 20 |

3 | 40-65 |

40-100 40-100 30-100 |

| FX200 | 200 |

40, 50, 55, 60 |

16, 20, 24, 28, 32 |

15 20 |

2 | 25-40 |

40-100 10-100 |

| FX165 | 165 |

40, 50, 55, 60 |

30, 35, 40, 45, 50 |

20 6 |

1.5 | 20-30 | 40-90 |

| FX150 | 150 |

30, 35, 40, 45, 50 |

8, 10, 12, 14, 16, 18, 20, 22 |

8 15 20 |

1.5 | 11-20 |

30-74 30-74 20-74 |

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now