Jaw Crusher

Part 1

Type:

Jaw crusher is often used for primary crusher and secondary crusher

Use:

which can be used to crush all materials with compressive strength below 320Mpa, such as basalt, granite, marble, limestone and so on

Model:

Big, Middle,Small (Feeding width)

Big>600mm;Middle300-600mm;Small<300mm

Part 2

power source: motor drive

First the motor feeds power to the skin through a triangular belt

Second the pulley, the pulley turns the eccentric shaft drive the jaw body to swing back and forth.

When the moving jaw plate moves close to the fixed jaw plate, it is broken

The volume of the cavity decreases, and the material in the broken cavity is crushed or cleaved

When the jaw plate moves, the volume of crushing cavity becomes larger.

Small pieces of broken material are discharged from the crushing chamber

The feed orifice is discharged, which makes a continuous circular motion,

Realize crushing operation.

General working process

Motor →Belt pulley→movable jaw→fixed jaw (again and again)

Part 3

Part 3

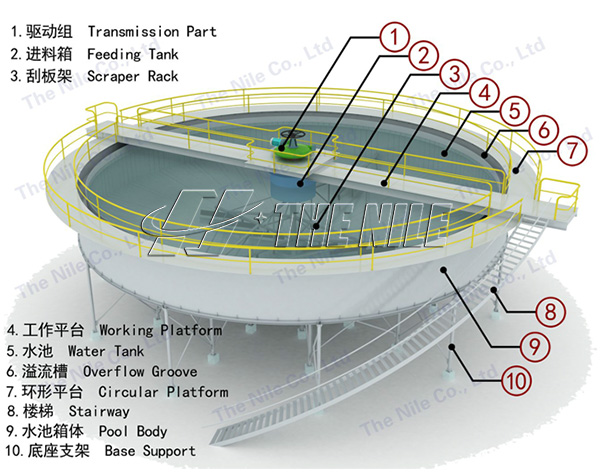

Main part of the Jaw crusher: rack section; Eccentric shaft rotating part; Working part of crushing chamber; safety device; Discharge port adjustment device

Part 4

PE jaw crusher advantages:High performance; good stability; high reliability; Easy to operate and maintain; wide application

Type:

Jaw crusher is often used for primary crusher and secondary crusher

Use:

which can be used to crush all materials with compressive strength below 320Mpa, such as basalt, granite, marble, limestone and so on

Model:

Big, Middle,Small (Feeding width)

Big>600mm;Middle300-600mm;Small<300mm

Part 2

power source: motor drive

First the motor feeds power to the skin through a triangular belt

Second the pulley, the pulley turns the eccentric shaft drive the jaw body to swing back and forth.

When the moving jaw plate moves close to the fixed jaw plate, it is broken

The volume of the cavity decreases, and the material in the broken cavity is crushed or cleaved

When the jaw plate moves, the volume of crushing cavity becomes larger.

Small pieces of broken material are discharged from the crushing chamber

The feed orifice is discharged, which makes a continuous circular motion,

Realize crushing operation.

General working process

Motor →Belt pulley→movable jaw→fixed jaw (again and again)

Main part of the Jaw crusher: rack section; Eccentric shaft rotating part; Working part of crushing chamber; safety device; Discharge port adjustment device

Part 4

PE jaw crusher advantages:High performance; good stability; high reliability; Easy to operate and maintain; wide application

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now