6-S Shaking table

1.Introduction of 6-S Shaking Table

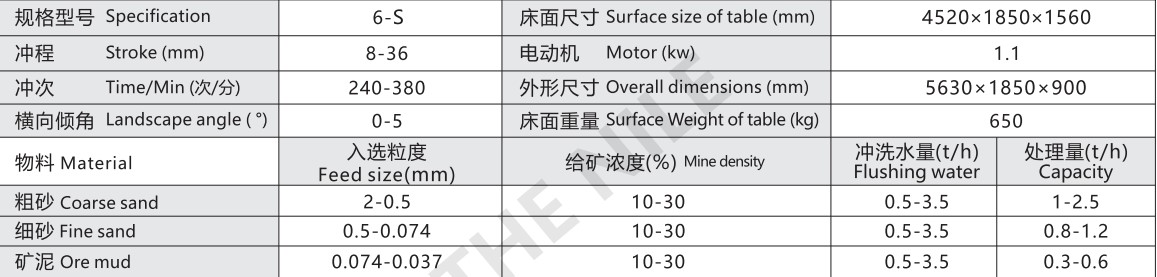

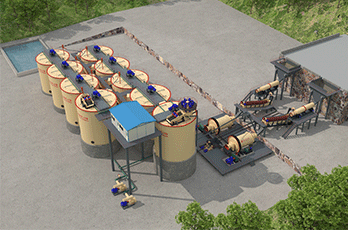

6-S shaking table is one of important equipment in gravity beneficiation process, which is applied in iron, manganese, coal, tungsten, tin, gold and other rare metal and precious metal beneficiation process. It can use roughing, concentrating, scavenging process and different particle of rough sand, fine sand and ore mud.

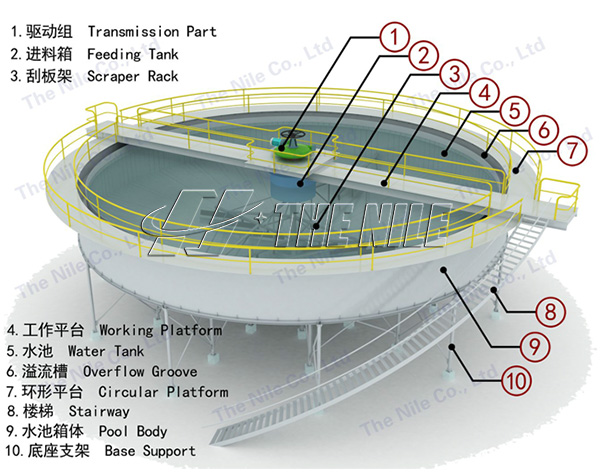

Shaking table is a common equipment for sorting fine-grained ores. It is usually composed of three parts: the bed surface, the frame and the transmission mechanism. In addition, there are also flushing troughs, ore feeding troughs, machine bases, etc. The entire bed surface is supported or lifted by the frame, and a slope adjustment device is installed on the frame.

2.Working principle of 6-S Shacking Table

The ore-dressing shaking table can make the ore particles move in different directions according to their density and particle size, and spread out in a fan shape along the diagonal line from the feed trough, and then be discharged along the edge of the bed surface in sequence. The discharge line is very long and can accurately produce a variety of products of different qualities, such as concentrate, sub-concentrate, middling concentrate and tailings, etc.

The shaking table uses gravity acceleration and water to separate heavy metal minerals from light impurities in the ore through vibration and inclined structure. It is an important equipment commonly used in metal ore processing and mineral processing.

3.Advantages of 6-S Shaking Table

Efficient sorting: It can effectively sort particles according to their weight and density, and is particularly suitable for the separation of heavy minerals such as metal ores and tungsten ores.

Easy operation: It is relatively simple to operate and maintain, and is suitable for industrial production and laboratory tests.

Strong adaptability: It can be adjusted and optimized according to the characteristics of different ores to improve recovery rate and product quality.

Environmental protection and energy saving: The shaker uses gravity and hydraulic power, does not require chemical agents, and has good environmental protection.

6-S shaking table is one of important equipment in gravity beneficiation process, which is applied in iron, manganese, coal, tungsten, tin, gold and other rare metal and precious metal beneficiation process. It can use roughing, concentrating, scavenging process and different particle of rough sand, fine sand and ore mud.

Shaking table is a common equipment for sorting fine-grained ores. It is usually composed of three parts: the bed surface, the frame and the transmission mechanism. In addition, there are also flushing troughs, ore feeding troughs, machine bases, etc. The entire bed surface is supported or lifted by the frame, and a slope adjustment device is installed on the frame.

2.Working principle of 6-S Shacking Table

The ore-dressing shaking table can make the ore particles move in different directions according to their density and particle size, and spread out in a fan shape along the diagonal line from the feed trough, and then be discharged along the edge of the bed surface in sequence. The discharge line is very long and can accurately produce a variety of products of different qualities, such as concentrate, sub-concentrate, middling concentrate and tailings, etc.

The shaking table uses gravity acceleration and water to separate heavy metal minerals from light impurities in the ore through vibration and inclined structure. It is an important equipment commonly used in metal ore processing and mineral processing.

3.Advantages of 6-S Shaking Table

Efficient sorting: It can effectively sort particles according to their weight and density, and is particularly suitable for the separation of heavy minerals such as metal ores and tungsten ores.

Easy operation: It is relatively simple to operate and maintain, and is suitable for industrial production and laboratory tests.

Strong adaptability: It can be adjusted and optimized according to the characteristics of different ores to improve recovery rate and product quality.

Environmental protection and energy saving: The shaker uses gravity and hydraulic power, does not require chemical agents, and has good environmental protection.

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now