Wet Pan Mill

1. Introduction of Wet Pan Mill

Wet Pan Mill is used for grinding gold ore, especially small rock stone with gold, which can grind into 100-150mesh. Many customers from Africa would like to import wet pan mill because of low cost and high productivity. The most important thing is that our customers can get pure gold directly after wet pan mill, which is suitable for people who want to begin small business.

2. Working Principle of Wet Pan Mill

The wet pan mill rotates continuously and grinds the ore by tumbling within the pan. As it rotates, the heavy ore particles are ground down and become fine slurry.

Water is usually added to the ore during grinding to facilitate the grinding process and to achieve a suitable slurry density for further separation.

After grinding, the slurry containing the finely ground ore particles is discharged from the wet pan mill. The next step typically involves gravity separation or other methods to separate the valuable minerals from the gangue (unwanted material).

In some cases, particularly for gold ore, the finely ground ore may be processed further through amalgamation with mercury to extract gold particles from the ore.

In some cases, particularly for gold ore, the finely ground ore may be processed further through amalgamation with mercury to extract gold particles from the ore.

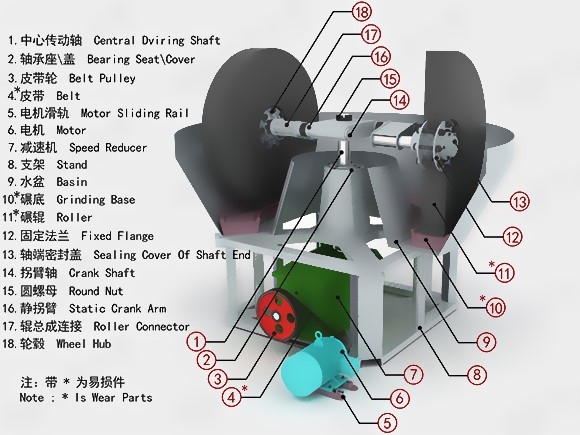

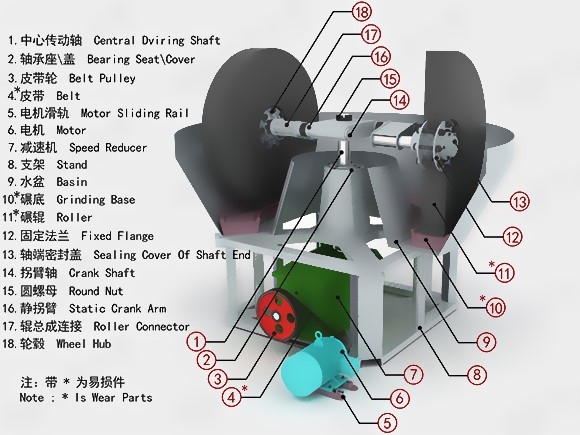

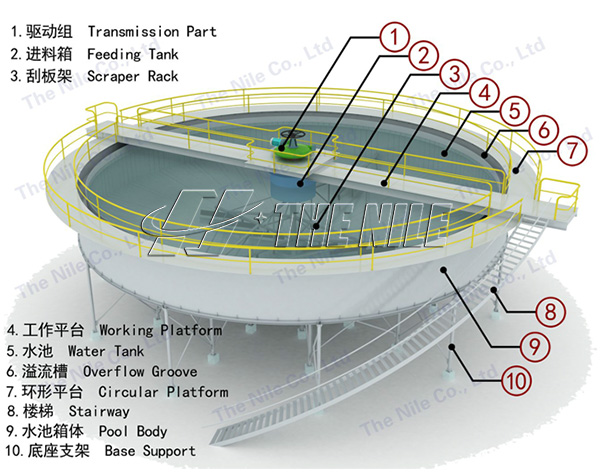

3. Structure of Wet Pan Mill

4.Factors affecting the grinding performance:

Material properties: The properties of the material being ground, such as its hardness, friability, and particle size, can affect the grinding performance of the mill. Harder and more friable materials will generally grind more easily than softer and more cohesive materials.

Water content: The water content of the material slurry affects the viscosity of the slurry and the grinding efficiency. A higher water content will generally result in finer grinding.

Grinding wheel speed: The speed of the grinding wheels affects the grinding force and the rate at which the material is ground. Higher grinding wheel speeds will generally result in finer grinding.

5.Advantages of Wet Pan Mill

Fine grinding: Wet mills can produce very fine particles, which is why they are well-suited for a wide variety of applications.

High throughput: Wet mills can handle high feed rates, which makes them suitable for large-scale production.

Closed-loop operation: Wet mills can be operated in a closed-loop system, which means that the material being ground is recirculated through the mill until the desired particle size is achieved. This allows for precise control of the particle size distribution.

Wet grinding: Wet grinding can help to prevent dust generation and minimize the risk of explosions.

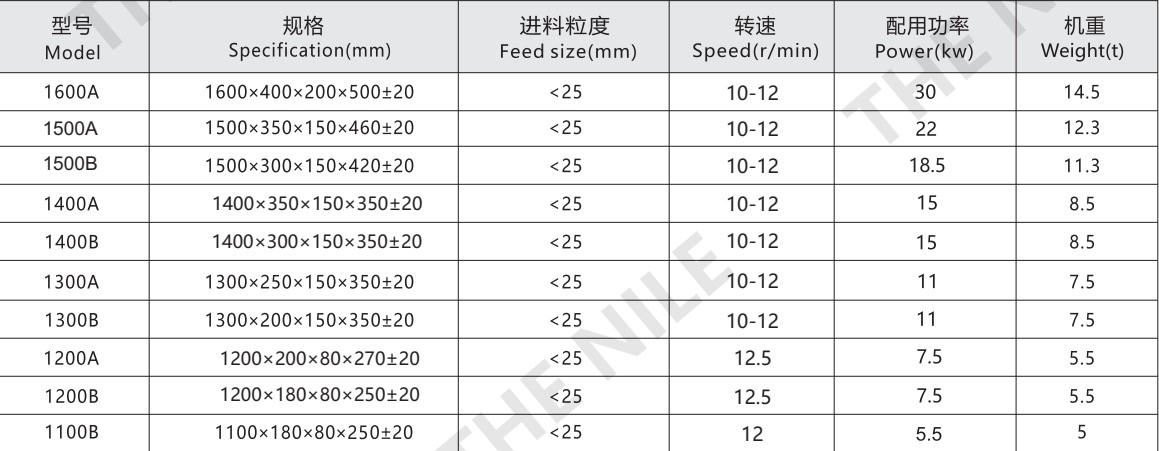

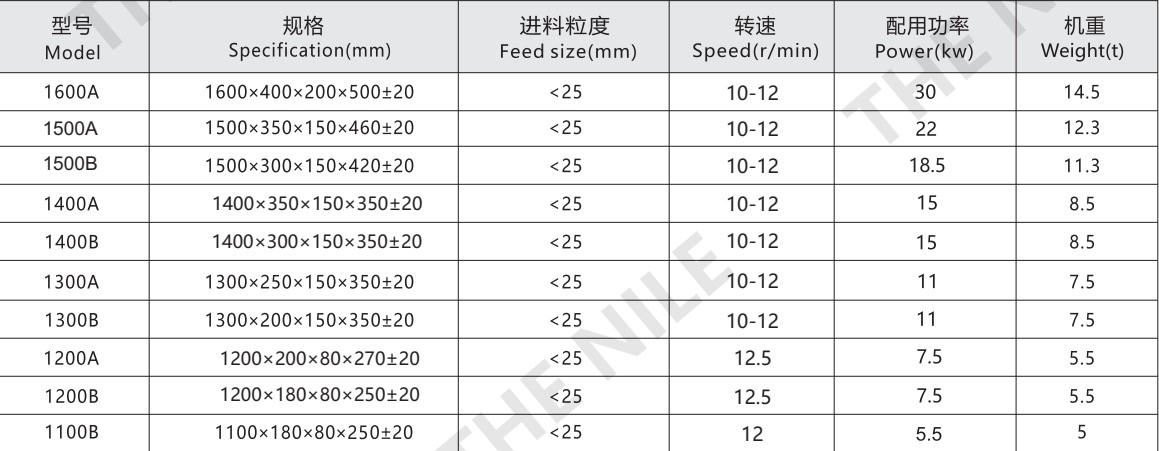

6.Main Technical Parameters

Wet Pan Mill is used for grinding gold ore, especially small rock stone with gold, which can grind into 100-150mesh. Many customers from Africa would like to import wet pan mill because of low cost and high productivity. The most important thing is that our customers can get pure gold directly after wet pan mill, which is suitable for people who want to begin small business.

2. Working Principle of Wet Pan Mill

The wet pan mill rotates continuously and grinds the ore by tumbling within the pan. As it rotates, the heavy ore particles are ground down and become fine slurry.

Water is usually added to the ore during grinding to facilitate the grinding process and to achieve a suitable slurry density for further separation.

After grinding, the slurry containing the finely ground ore particles is discharged from the wet pan mill. The next step typically involves gravity separation or other methods to separate the valuable minerals from the gangue (unwanted material).

In some cases, particularly for gold ore, the finely ground ore may be processed further through amalgamation with mercury to extract gold particles from the ore.

In some cases, particularly for gold ore, the finely ground ore may be processed further through amalgamation with mercury to extract gold particles from the ore.

3. Structure of Wet Pan Mill

4.Factors affecting the grinding performance:

Material properties: The properties of the material being ground, such as its hardness, friability, and particle size, can affect the grinding performance of the mill. Harder and more friable materials will generally grind more easily than softer and more cohesive materials.

Water content: The water content of the material slurry affects the viscosity of the slurry and the grinding efficiency. A higher water content will generally result in finer grinding.

Grinding wheel speed: The speed of the grinding wheels affects the grinding force and the rate at which the material is ground. Higher grinding wheel speeds will generally result in finer grinding.

5.Advantages of Wet Pan Mill

Fine grinding: Wet mills can produce very fine particles, which is why they are well-suited for a wide variety of applications.

High throughput: Wet mills can handle high feed rates, which makes them suitable for large-scale production.

Closed-loop operation: Wet mills can be operated in a closed-loop system, which means that the material being ground is recirculated through the mill until the desired particle size is achieved. This allows for precise control of the particle size distribution.

Wet grinding: Wet grinding can help to prevent dust generation and minimize the risk of explosions.

6.Main Technical Parameters

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now