Mobile Trommel Gold Wash Plant

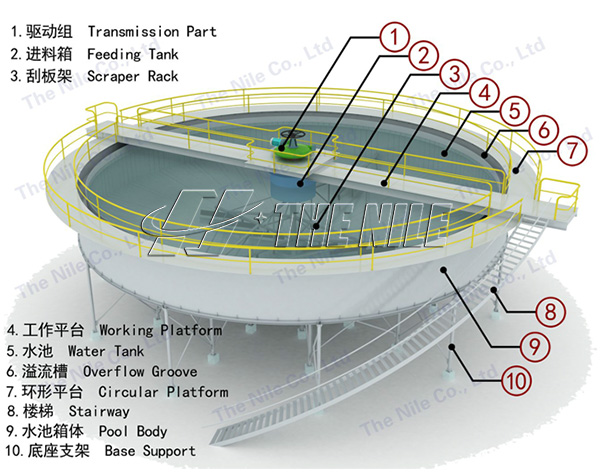

The Main structure of the GTS drum screen is a screening cylinder, which is composed of several circular meshes and also inclined with the ground; outside is sealed by the sealing guard to prevent environmental pollution. Through variable speed deceleration system, the screening cylinder is rotated at a certain rotation speed, and the material is separated from the top to the bottom through the screening cylinder, the fine material is discharged from the lower part of the front end of the screening cylinder, and the coarse material is discharged from the lower end of the screening cylinder. The drum screen ( cylinder rotary screen ) can be provided with a comb-shaped cleaning mechanism, and the relative movement of the comb-shaped cleaning mechanism and the screening cylinder can be achieved the effect of cleaning the sieve body without any interruption during the screening process, so that the sieve and the splitting cylinder is always clear, nonsticky, non-blocking and does not affect the screening effect throughout the working process.

Working principle of mobile gold wash plant

Working principle of mobile gold wash plant

Mobile gold screening uses vibrating screening technology to separate gold ore from other materials in a mixture through vibration. The vibration of the screen allows gold ore particles to pass through the screen, while larger waste materials are retained on top. The design of the mobile device allows the screening process to be carried out at different locations, providing flexibility and efficiency.

Placer Gold Washing Plant is a kind of combined gold mining machine , designed especially for placer gold mine which is contained in the raw material, includes sieving, separating through trammel, sluice and extraction gold progress. It is with wheel type chassis, can be driven by vehicles and move easily. Choose placer gold washing equipment can also according to the situation of ore body with fixed chute, shaking chute or centrifugal concentrator, shaking table,Amalgamator,gold furnace and so on.

Main Features of mobile gold wash plant

Main Features of mobile gold wash plant

1. There is a directive wheel in the front wheel of the Trommel, so the mobile can make turns freely.

2. There is an adjustment gear in the chain, when the chain is loose, it can be adjusted easily. And there are ladders on each side of the mobile trommel, people can get on the top of the trommel to check easily.

3. When the diesel engine starts, the speed reducer and trommel won’t start with the diesel, there is a clutch between the diesel engine and the speed reducer. When the diesel engine runs freely, then put through the clutch, the speed reducer and Trommel run.

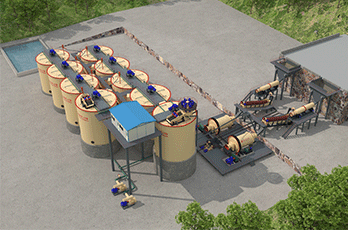

Complete production line:

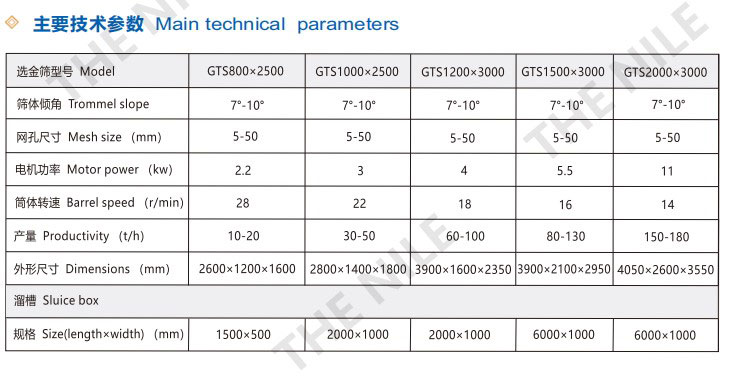

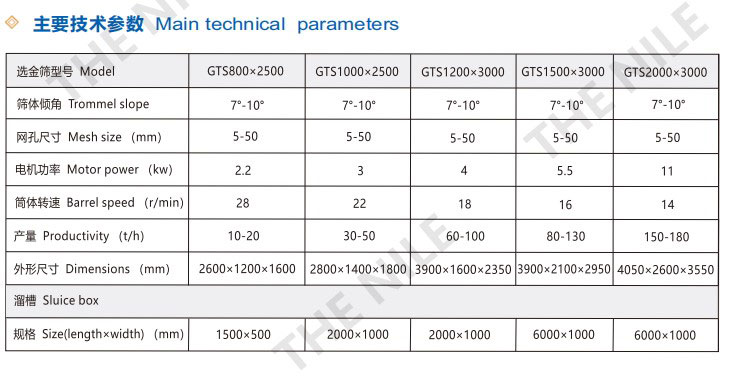

Main technical parameters:

Main technical parameters:

Mobile gold screening uses vibrating screening technology to separate gold ore from other materials in a mixture through vibration. The vibration of the screen allows gold ore particles to pass through the screen, while larger waste materials are retained on top. The design of the mobile device allows the screening process to be carried out at different locations, providing flexibility and efficiency.

Placer Gold Washing Plant is a kind of combined gold mining machine , designed especially for placer gold mine which is contained in the raw material, includes sieving, separating through trammel, sluice and extraction gold progress. It is with wheel type chassis, can be driven by vehicles and move easily. Choose placer gold washing equipment can also according to the situation of ore body with fixed chute, shaking chute or centrifugal concentrator, shaking table,Amalgamator,gold furnace and so on.

1. There is a directive wheel in the front wheel of the Trommel, so the mobile can make turns freely.

2. There is an adjustment gear in the chain, when the chain is loose, it can be adjusted easily. And there are ladders on each side of the mobile trommel, people can get on the top of the trommel to check easily.

3. When the diesel engine starts, the speed reducer and trommel won’t start with the diesel, there is a clutch between the diesel engine and the speed reducer. When the diesel engine runs freely, then put through the clutch, the speed reducer and Trommel run.

Complete production line:

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now