Reveal the Secret of Jaw Crushers: An Illustrated Guide to Vulnerable Parts and Longevity Strategies

On bustling industrial production lines, jaw crushers have gained immense popularity for their powerful crushing ability and stable performance. However, over time, the vulnerable parts of these machines inevitably experience wear and tear, affecting their overall lifespan and crushing efficiency. So, how do we properly understand and maintain these vulnerable parts to ensure that our jaw crushers retain their vitality for longer? Today, let's delve into the world of jaw crushers and uncover the secrets to their "everlasting" myth!

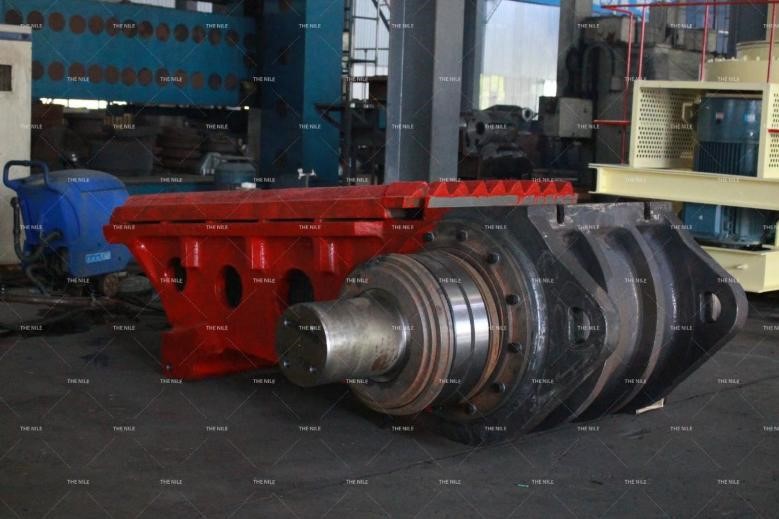

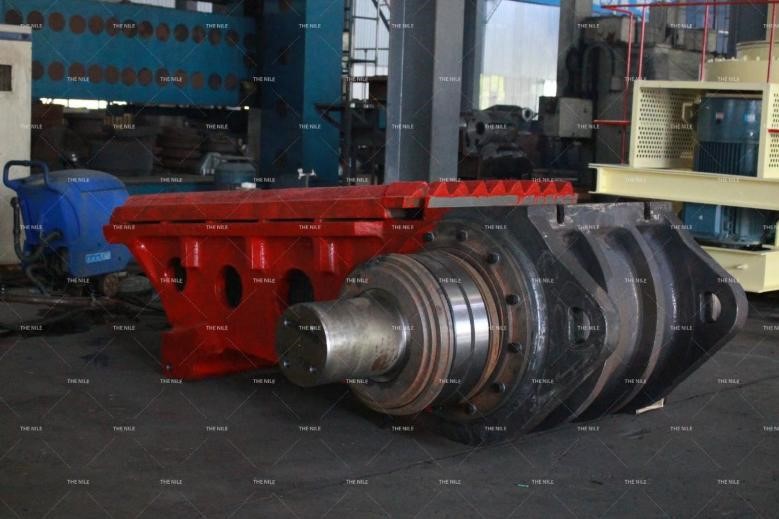

The vulnerable parts of a jaw crusher primarily include the jaw plates, bearings, tooth plates, and flywheels. These components endure significant impact and abrasion during operation, thus requiring special attention for maintenance and replacement.

1. Jaw Plates: The jaw plates are the main part of a jaw crusher, responsible for crushing materials. Due to constant contact with materials, the jaw plate surfaces are prone to wear and cracks. Regular inspections of the jaw plates' wear conditions and timely replacement of severely worn ones are crucial for ensuring the smooth operation of the equipment.

2. Bearings: Bearings support the rotary motion of the jaw crusher, enduring immense pressure and friction. Damaged or worn bearings can lead to unstable operation and even safety hazards. Regular checks of the bearings' lubrication and wear conditions, as well as prompt replacement of damaged ones, are essential for extending the equipment's lifespan.

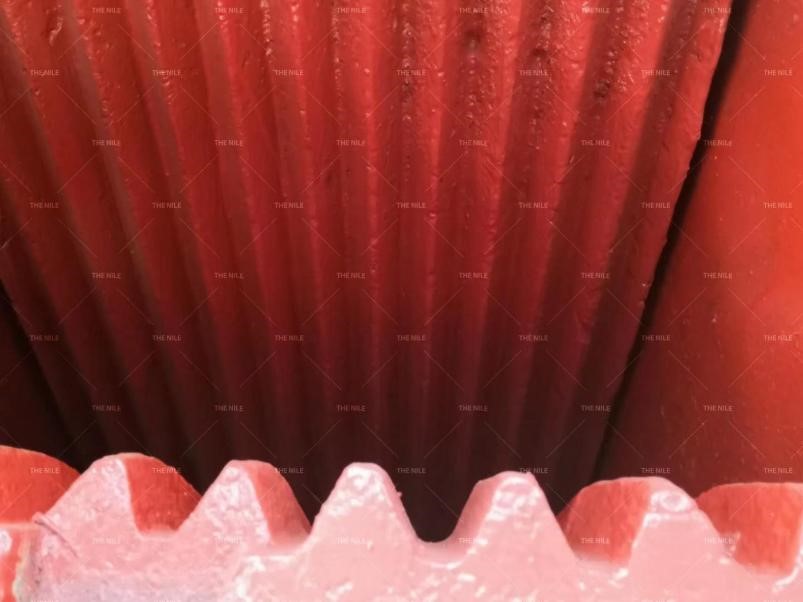

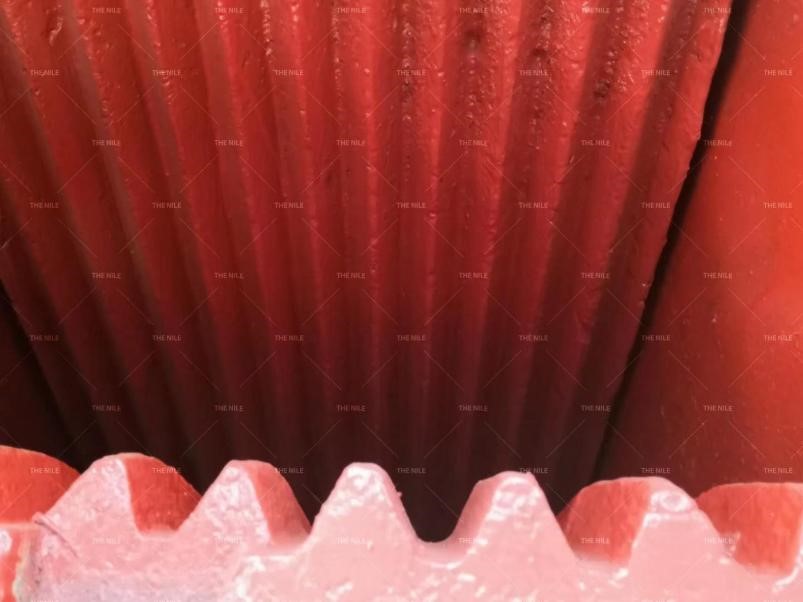

3. Tooth Plates: The tooth plates are part of the crushing mechanism in a jaw crusher, featuring sharp teeth for crushing materials. Over time, the tooth plates experience wear and deformation, affecting the crushing efficiency. Regular inspections of the tooth plates' wear conditions and timely replacement of worn ones are crucial for ensuring optimal crushing results.

4. Flywheels: Flywheels are the power transmission components of a jaw crusher, providing stable power support. Prolonged use can lead to wear and cracks in the flywheels, affecting the stability and safety of the equipment. Regular inspections of the flywheels' wear conditions and prompt replacement of damaged ones are essential for ensuring safe operation.

To ensure that your jaw crusher retains its vitality for longer, apart from paying attention to the maintenance and replacement of vulnerable parts, there are some practical longevity strategies to consider.

1. Reasonable Usage: Always adhere to the equipment's operation manual and avoid overloading or overspeeding. Regular maintenance of the equipment is also crucial to keep it in its best condition.

2. Quality Components: Choosing quality vulnerable parts and components can reduce wear and tear on the equipment, extending its lifespan. Therefore, always purchase these parts from reliable sources and well-known brands.

3. Lubrication Maintenance: Lubrication is essential for ensuring the smooth operation of a jaw crusher. Regular checks of the equipment's lubrication status and timely addition or replacement of lubricants are crucial to ensure that all components are well-lubricated.

4. Regular Inspections: Conduct comprehensive inspections of your jaw crusher regularly to identify and address potential issues promptly. Preventive maintenance can effectively extend the equipment's lifespan.

In conclusion, by properly understanding and maintaining the vulnerable parts of your jaw crusher and employing practical longevity strategies, you can ensure that this industrial workhorse retains its vitality for longer, contributing significantly to your production line!

I. An Illustrated Guide to Jaw Crusher's Vulnerable Parts

The vulnerable parts of a jaw crusher primarily include the jaw plates, bearings, tooth plates, and flywheels. These components endure significant impact and abrasion during operation, thus requiring special attention for maintenance and replacement.

1. Jaw Plates: The jaw plates are the main part of a jaw crusher, responsible for crushing materials. Due to constant contact with materials, the jaw plate surfaces are prone to wear and cracks. Regular inspections of the jaw plates' wear conditions and timely replacement of severely worn ones are crucial for ensuring the smooth operation of the equipment.

II. Strategies for Extending Jaw Crusher's Lifespan

To ensure that your jaw crusher retains its vitality for longer, apart from paying attention to the maintenance and replacement of vulnerable parts, there are some practical longevity strategies to consider.

1. Reasonable Usage: Always adhere to the equipment's operation manual and avoid overloading or overspeeding. Regular maintenance of the equipment is also crucial to keep it in its best condition.

2. Quality Components: Choosing quality vulnerable parts and components can reduce wear and tear on the equipment, extending its lifespan. Therefore, always purchase these parts from reliable sources and well-known brands.

3. Lubrication Maintenance: Lubrication is essential for ensuring the smooth operation of a jaw crusher. Regular checks of the equipment's lubrication status and timely addition or replacement of lubricants are crucial to ensure that all components are well-lubricated.

4. Regular Inspections: Conduct comprehensive inspections of your jaw crusher regularly to identify and address potential issues promptly. Preventive maintenance can effectively extend the equipment's lifespan.

In conclusion, by properly understanding and maintaining the vulnerable parts of your jaw crusher and employing practical longevity strategies, you can ensure that this industrial workhorse retains its vitality for longer, contributing significantly to your production line!

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now