A Multi-Purpose Grinding Equipment: Wet Pan Mill

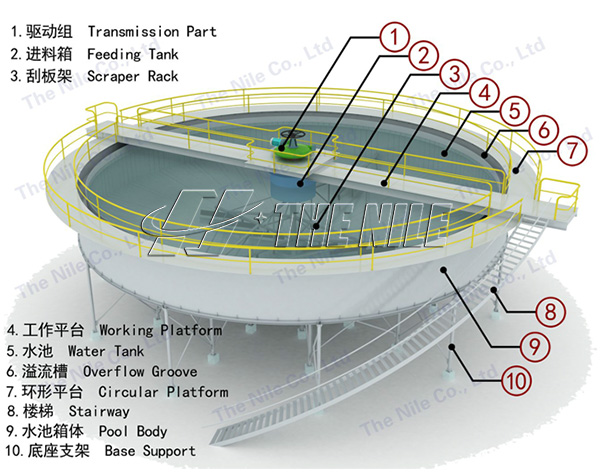

Wet pan mill is a multi-purpose grinding equipment, not only used for grinding ore, but also for mixing gold with mercury. The wet grinding machine mainly achieves moisture balance and uniform slurry fineness by repeatedly stirring, crushing and rolling the raw materials, thereby improving production efficiency. Characterized by good wet crushing performance, low investment, and high output, it is a good substitute for small and medium-sized ball mills. The equipment can also be used to recycle tailings in the iron ore process to prevent the loss of mineral powder and make full use of effective resources.

The wet pan mill is mainly composed of the frame, water basin, rolling wheels, rolling plate, motor, reducer and other components. First, the electric motor transmits the power to the reducer. Driven by the reducer, the torque is transmitted to the horizontal axis above through the large vertical shaft, and then transmitted to the grinding wheels through the tie rods installed at both ends of the horizontal axis, so that the grinding wheels moves counterclockwise along the horizontal axis. The wheels can not only rotate around the large vertical axis, but also revolve on its own axis, while the grinding plate is fixed. The ore material will be repeatedly squeezed, crushed and ground because of the squeezing force from the weight of the grinding wheel and the huge friction force generated by the grinding wheels and the plate when the wheels revolve and rotate.

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now