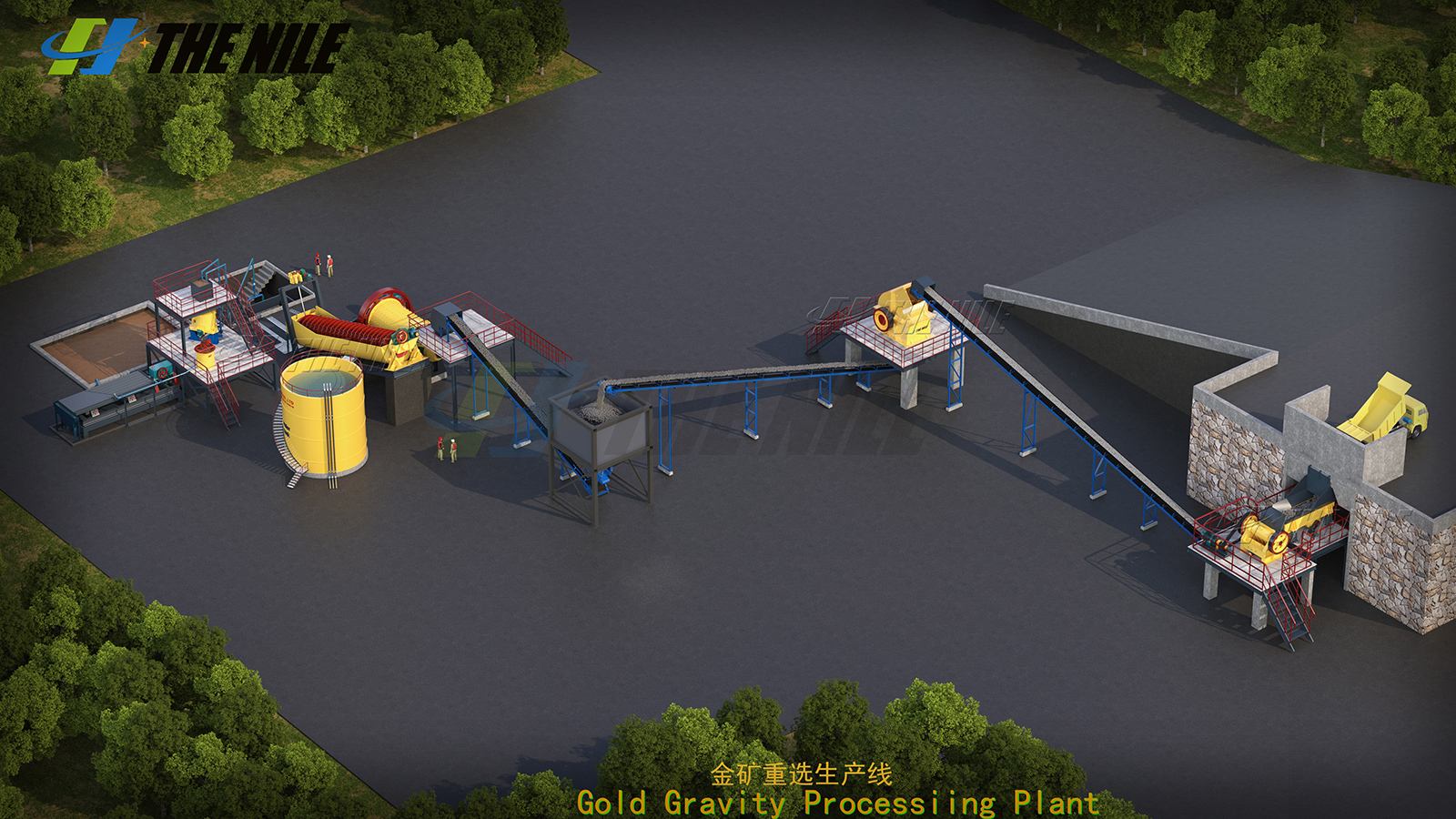

3-5T/H Gold gravity separation process plant

Gold gravity separation is a beneficiation method. Gravity separation principle: It realizes the process of separating ore particles according to density according to different densities of various minerals and different gravity, fluid movement and other mechanical forces in moving media.

Easy ways to get the answers you need. Service Online

Process introduction:

Gold gravity separation is a beneficiation method. Gravity separation principle: It realizes the process of separating ore particles according to density according to different densities of various minerals and different gravity, fluid movement and other mechanical forces in moving media.

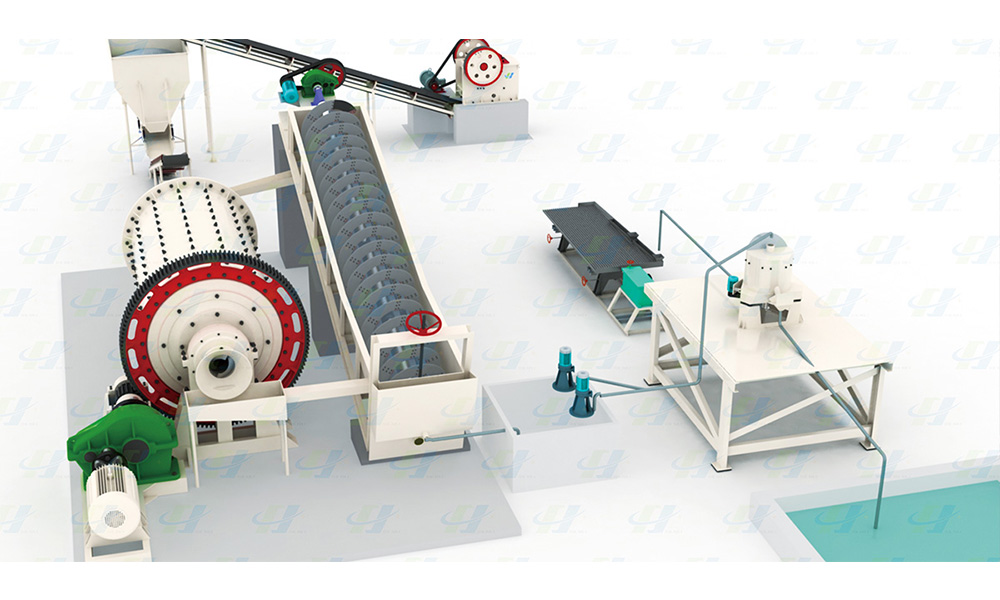

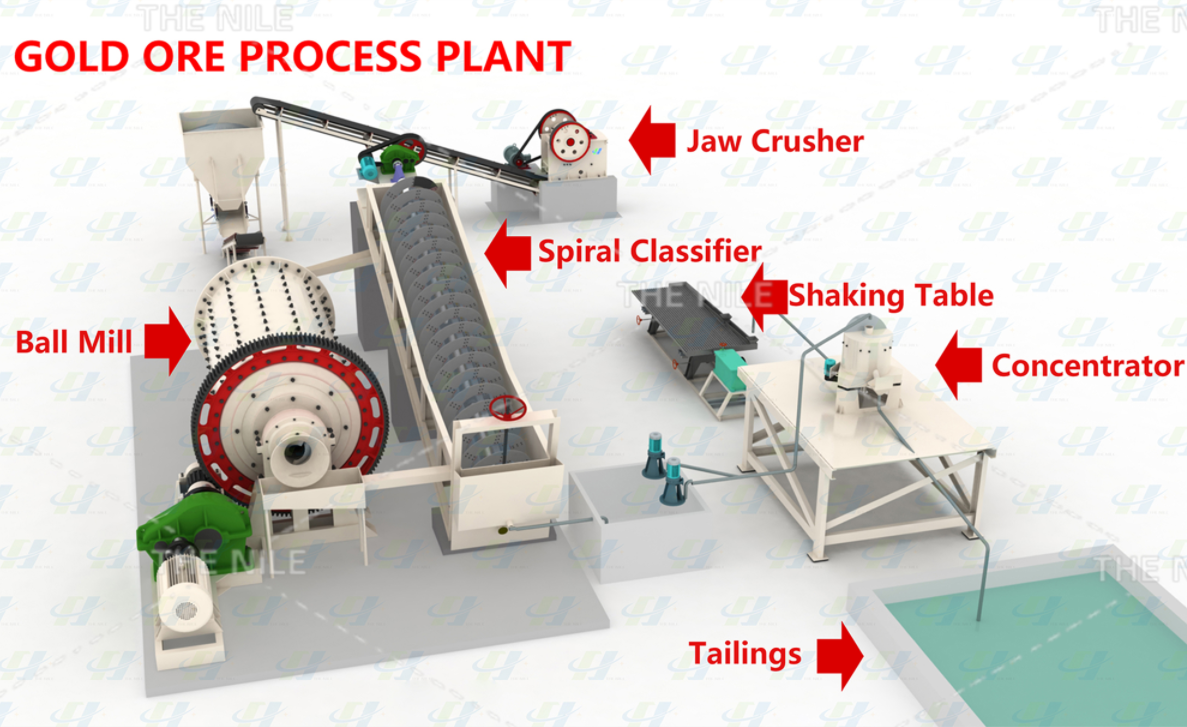

Small and middle scale gold gravity separation processing plant

Original gold ore is crushed into under 15mm by a jaw crusher.

After crushing, the material is transported into the ball mill. After being ground by a ball mill, some of the rock stones are ground into 200 mesh.

Then spiral classifier can screw back big particles into the ball mill and grind bigger stones again, until we can get the qualified product.

The qualified product is pumped into a centrifugal gold concentrator, and after the eccentric process, we can obtain part of a gold particle in the concentrator.

Also, we can add a shaking table at the final stage, which can obtain some fine gold.

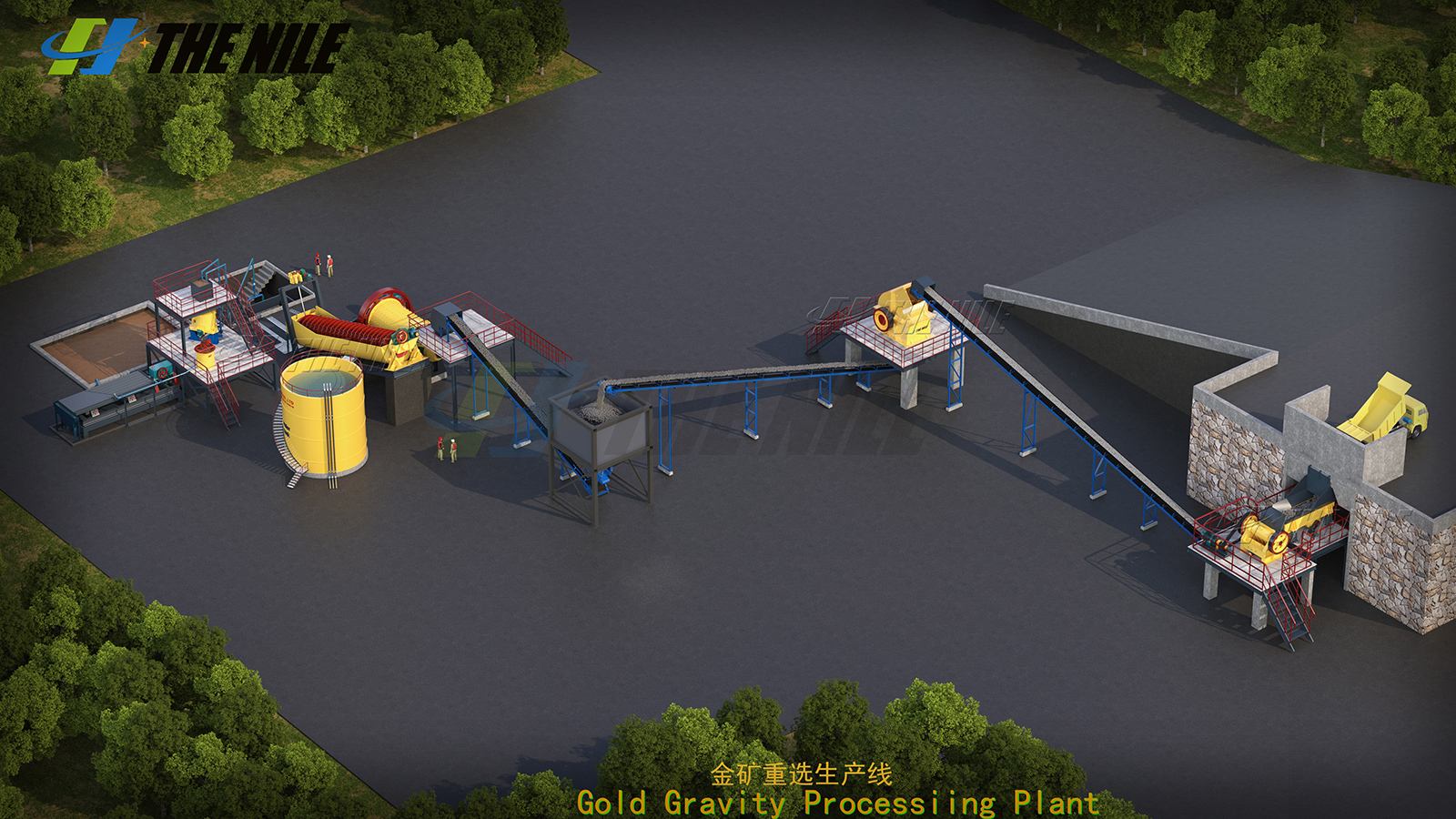

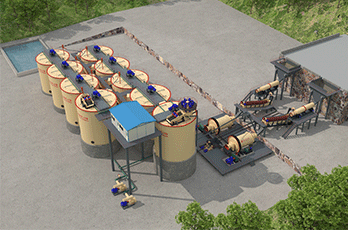

Gold gravity processing plant set in Africa

Customer feedback: The Nile has rich engineering experience and professional technical advantages, providing us with one-stop customized engineering solutions such as pre-planning, EPC, financing, maintenance, etc. We are very satisfied with the machine and the solution.

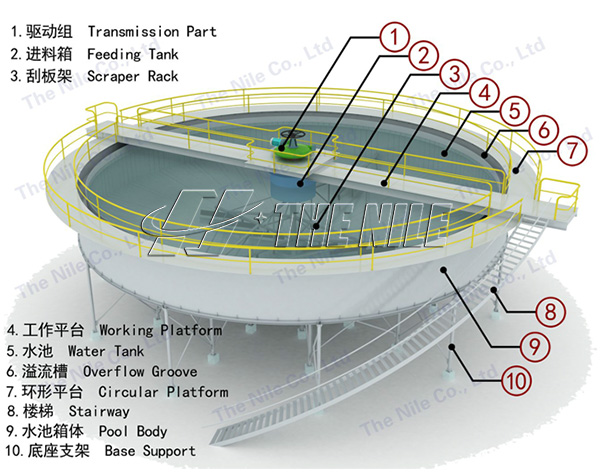

Gold gravity equipment

Main equipment used in this gold ore processing plant: jaw crusher, ball mill, spiral classifier, shaking table, gold centrafugal concentrator.

The Nile has designed several different gold processing plant to meet the customers' need, next is anothe plan to extract gold from ore.

Firstly, use drum screen to screen out big particle, then roughing by using gold centrifugal concentrator, finally concentrating by using shaking table.

Gold gravity separation is a beneficiation method. Gravity separation principle: It realizes the process of separating ore particles according to density according to different densities of various minerals and different gravity, fluid movement and other mechanical forces in moving media.

Small and middle scale gold gravity separation processing plant

Original gold ore is crushed into under 15mm by a jaw crusher.

After crushing, the material is transported into the ball mill. After being ground by a ball mill, some of the rock stones are ground into 200 mesh.

Then spiral classifier can screw back big particles into the ball mill and grind bigger stones again, until we can get the qualified product.

The qualified product is pumped into a centrifugal gold concentrator, and after the eccentric process, we can obtain part of a gold particle in the concentrator.

Also, we can add a shaking table at the final stage, which can obtain some fine gold.

Gold gravity processing plant set in Africa

Customer feedback: The Nile has rich engineering experience and professional technical advantages, providing us with one-stop customized engineering solutions such as pre-planning, EPC, financing, maintenance, etc. We are very satisfied with the machine and the solution.

Gold gravity equipment

Main equipment used in this gold ore processing plant: jaw crusher, ball mill, spiral classifier, shaking table, gold centrafugal concentrator.

Firstly, use drum screen to screen out big particle, then roughing by using gold centrifugal concentrator, finally concentrating by using shaking table.

Advantages of Gold mine garavity processing plant:

1. Energy saving

2. Less water consumption

3. Low equipment investment

4. Suitable for intermittent operation

5. Easy to maintain

6. Environmentally friendly with no mercury

6. Environmentally friendly with no mercury

Request for Quotation

You can get the price list and a NILE representative will contact you within one business day.

WhatsApp

WhatsApp E-mail

E-mail Chat Now

Chat Now